Stunning Info About How To Reduce Inventory Levels

Manufacturing or distributing more quickly.

How to reduce inventory levels. Divide the cost of all stocks you handle or sell by the number of days they will last. Place more accurate orders with vendors; The fastest way to reduce your inventory is simply by delisting (stop selling) losers.

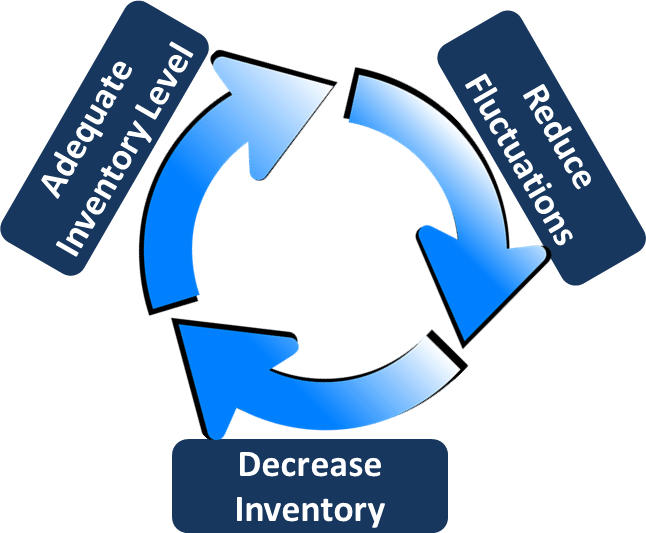

By keeping your inventory levels low, you will: How to reduce inventory using stock classification 2. Too much inventory can require too much.

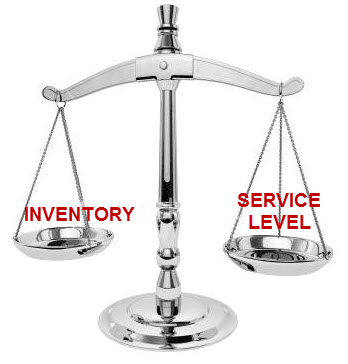

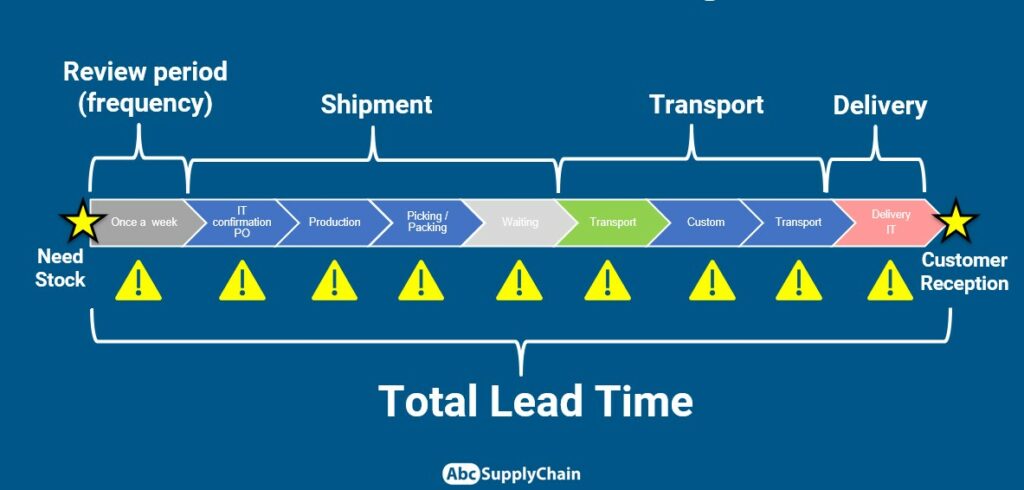

Shorter lead times mean less inventory is required. Accurate sales forecasts are a must if you want to keep a healthy stock level. Inventory and supply chain managers are often tasked with reducing inventory levels while maintaining.

Calculate how much inventory you currently have on hand. It gives you the cost of inventory that you. Top five inventory reduction methods 1.

If you have 100 units in your stockroom but 80 recorded in your inventory management system, for example, your inventory accuracy would be 80%. Investigate ways of speeding up the flow of purchases and delivery times. A common result of poor production scheduling is product flow imbalances, causing bottlenecks and reduced throughput.

These are low volume items which sit around in your warehouse for months just taking up space and. Bottled water manufacturer, researchers at mit’s center for transportation & logistics developed an analytical framework to effectively right size. If your sales forecast is.